Hydro-Transport Food Pumps

Cornell Pumps Save Costs!

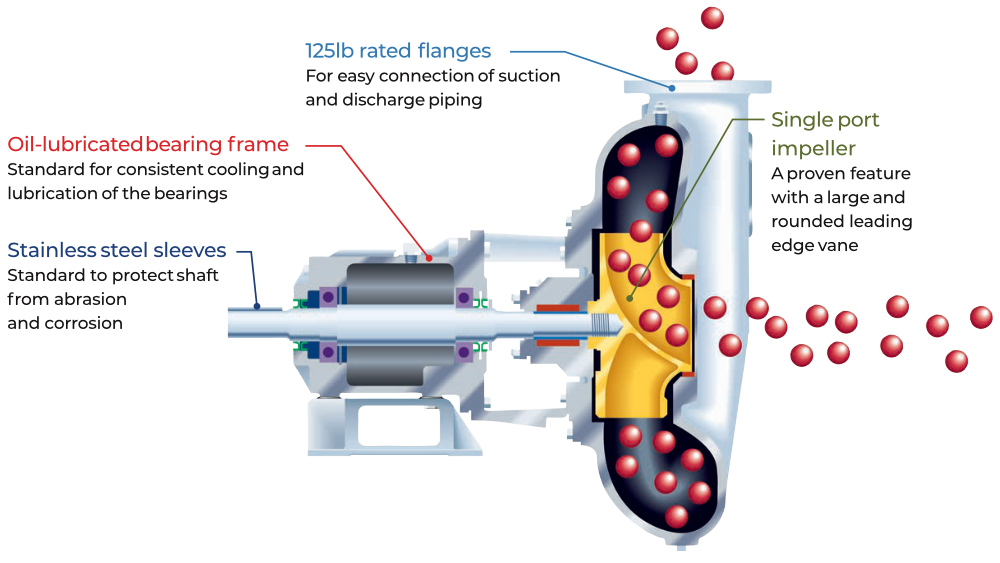

Cornell engineers understand the important role food handling pumps play in today’s marketplace. Our innovative single port impeller configuration, with its unique offset volute, provides the end user with a food handling pump capable of transporting even the most delicate food products.

At Cornell, we’ve built our worldwide reputation on quality and reliability. Our centrifugal pumps are engineered and manufactured to provide continuous and trouble-free operation. Many Cornell pumps sold in the 1950’s are still providing the same dependable service they did the day they were installed. No one is more committed to making your ownership a truly rewarding experience than Cornell.

Many Cornell innovations have evolved from our commitment to the food processing industry and an ongoing effort to work with customers to provide optimal solutions for food handling applications.

Efficiency

In addition to having reliable operation, today’s food process systems must also be efficient and economical. As energy costs rise, conservation and efficiency become critical issues for end-users striving to minimize expenses associated with energy consumption. Cornell pumps maintain superb hydraulic operating efficiencies and are coupled with energy-efficient motors.

Materials of Construction

- Ductile iron or 304SS construction on PP series

- Cast iron or ductile iron on P series

- Standard SAE 1144 Stressproof steel shaft; 17-4PH shaft optional

- 416SS shaft sleeve

- 304SS impellers standard on 4NMP, 4NMPP, 6NHP, 6NHPP, and 8NHPP

- Other construction materials available, including 316 stainless steel

Features:

- PP series pumps have Cornell’s exclusive offset and expanded volute

- Food grade packing standard

- Available Cycloseal® sealing system with tungsten carbide vs. silicon carbide faces

- Electro-polish on 304 Stainless Steel Pumps

- Optional clean-out port

- Two-year warranty

Performance Focused Pump Design

Cornell’s distinctive volute design allows food to pass through the pump and exit through the center of

the discharge nozzle while minimizing contact with any pump surface. The single port impeller, a proven feature consisting of a large and rounded leading edge vane, was designed specifically for handling whole or processed foods. Together, these features significantly reduce product damage and abrasion, thus insuring product integrity.